Horizontal Plastic Injection Moulding Machine Manufacturer

KSB MACHINERY LLP is the top Horizontal Plastic Injection Moulding Machine Manufacturer for 2 decades. Our company’s success is based on our consistent efforts, moral ethics, dedication, and client gratification. Our cutting-edge production facilities inspire us to create a high performance line of plastic injection moulding machines.

Horizontal injection moulding machine has traditionally been the most popular type of injection moulding. The mould in horizontal injection moulding machine opens and closes along a horizontal axis. Because of this structure, steady, accurate injection pressure is necessary to fill the mould cavities and aid in effective packing and cooling. Furthermore, because the mould halves are horizontally separated, formed products from these mould automatically fall out of the cavity during ejection and do not need to be manually retrieved.

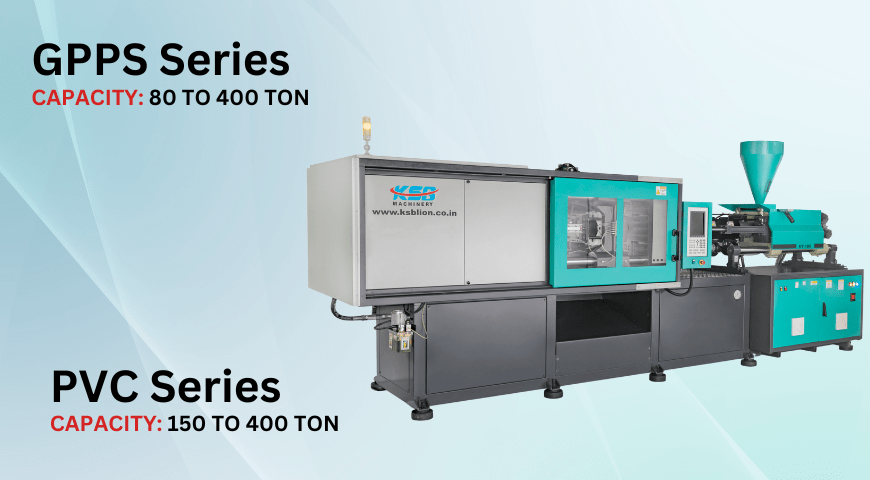

KSB manufactures Servo Series, Toggle injection moulding machine for GPPS and PVC plastic materials. Our Horizontal Injection Moulding Machine are reliable-power efficient-consistent-proven in the plastic moulding industry for trouble free long life Operation with minimum Maintenance cost. Available in standard sizes of 80 Tons to 400 Tons with Microprocessor Controls and Proportional Flow / Pressure Hydraulics to ensure repeatability with high production rates. We also develop and deliver customise requirement horizontal injection moulding machine for our clients.

Horizontal Injection Moulding Machine provides the flexibility to generate designs forms in a wide range of sizes from small to large plastic products, and can be used to manufacture a wide range of solid parts such as bottle caps, containers, computers, electronic housings, agricultural products, toys, machinery components, television components, outdoor furniture, and much more.

Advantages Of Horizontal Injection Moulding Machine

- Capability to execute tasks at a high pace of production.

- Very less material loss.

- Product finishing time is minimal.

- Accurate tolerance repeatability

- Due to auto product ejection labour cost is low.

- A variety of plastic materials are available for various plastic products

Key Characteristics Of Horizontal Injection Moulding Machine

High

Productivity

Low Power Consumption

Precision & Consistency

Robust Construction

Horizontal Injection Moulding Machine Specification

Capacity: 80 to 400 Ton Locking

Clamp Style: Toggle Locking

Clamping Force: 80 to 400 Ton

Machine Structure: Horizontal Injection Molding Machine

Machine Series: GPPS Series

Material: GPPS Plastics & PVC/UPVC Plastic

Maximum Injection Pressure: 2175 TO 2279 Bar

Horizontal Injection Moulding Machine Features

- Process Parameter Monitoring for last 150 cycles

- TFT Color Display with Alpha – Numeric Keypad

- Actual Injection Speed & Pressure Graph Display

- 50 Mould Data Storage Configurable Multilevel Password

- Graphically Presentation of Hourly Production

- High/Low Limit Display for Each Adjustable Parameter

- 1/0 diagnosis – Analog & Digital

- Timer Precision in 0.01 Second

- Process Mode: Function with its Co-function on a Single Key Press

- Over View Screen with Graphical Display of Machine Functions

- Soft Keys for Fast Access of Select Menus

- Visual & Audible Alarm 100 Alarm History with Date & Time Log

- 2 Stage Injection Speed & 2 Stage Injection Pressure Profile

- 2 Stage Screw Speed & 2 Stage Back Pressure Control (Setting) through Screen

- Digital setting of Screw RPM & Digital Read out of Actual RPM

- Wide Choice of Injection Units with A-B-C Screw/Barrel Combinations

- Linear Position Transducer for Accurate Injection Position Control

- Injection Decompression Before/After Refilling or Both

- Semi-Auto Purge, Intrusion Moulding Programs

- Aluminum Chequered Plate below Purge Area

- Actual Current Display of Heating Zones

- Heater Failure & Thermocouple Failure Detection

- Accurate PID Temperature Control settable on Screen

- Auto Heat Startup & Shutdown

- Heat Standby after set number of Cycles

- High / Low Temperature Alarm

- Set & Actual Temperature Data

- Energy Efficient Servo System

- Pump & Motor On Vibration Pad For Smooth Machine operation

- Hydraulic Layout for Easy Approach

- Valves Placed near Actuators for Rapid Response

- Pre-Heating Circuit for Hydraulic Oil

- Low Oil Level Audible Alarm & Motor Shut Down

- Continuous Oil Filtration with 10 micron Filter

- Robust Toggle Clamp Mechanism

- Quick Automatic Mould Height & Tonnage

- Adjustable Pressure setting of Closing & Opening Stage

- Proportional Speed Control with 5 Closing & 5 Opening Speed

- Adjustable 2 Stage Mould Safety Pressure & 1 Stage Speed

- Position Based Ramping for Accurate Position Switching,

- Precise Speed & Pressure Control

- Linear Position Transducer for Accurate Clamp Position Control

- Stage Wise Actual Time Display

- Knock-Out Bar

- 2 Stage Programmable Ejector Forward Profile with Soft Eject

- Ejector Speed & Pressure adjustable on Screen

- Linear Transducer for Ejector Position

- Pulsating Ejector Strokes

- Ejector Stay Forward & Forward Dwell Timer

Horizontal Injection Moulding Machine Videos

Horizontal Injection Moulding Machine Price

The price of our Horizontal injection moulding machine can differ significantly depending on its type, size, and features. The type of machine needed often corresponds to the type of plastic products being manufactured. Additionally, certain machines may require supplementary components. Moreover, the cost of the machine is influenced by its type; for instance, hydraulic machines tend to be less expensive compared to automatic ones. Considerations such as installation, support, and maintenance should also be factored in when inquiring about the price of a machine. KSB’s horizontal plastic injection moulding machine range is between 15 and 45 lakh. For a more precise pricing estimate, please reach out to us at +91-9824023849 or sales@ksblion.co.in.