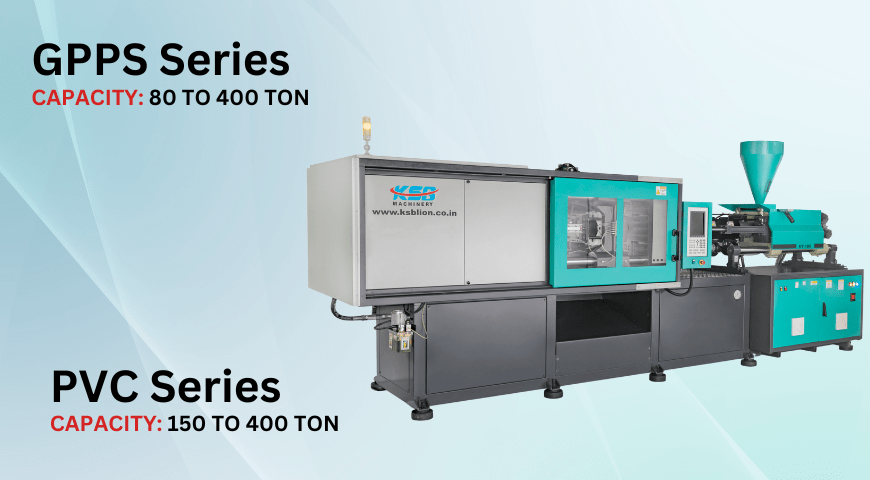

Horizontal Plastic Injection Moulding Machine Manufacturer

KSB MACHINERY LLP is the top Horizontal Plastic Injection Moulding Machine Manufacturer for 2 decades. Our company’s success is based on our consistent efforts, moral ethics, dedication, and client gratification. Our cutting-edge production facilities inspire us to create a high performance line of plastic injection moulding machines.

Horizontal injection moulding machine has traditionally been the most popular type of injection moulding. The mould in horizontal injection moulding machine opens and closes along a horizontal axis. Because of this structure, steady, accurate injection pressure is necessary to fill the mould cavities and aid in effective packing and cooling. Furthermore, because the mould halves are horizontally separated, formed products from these mould automatically fall out of the cavity during ejection and do not need to be manually retrieved.

KSB is Top Plastic Injection Moulding Machine Manufacturer in India provides Servo Series, Toggle injection moulding machine for GPPS and PVC plastic materials. Our Horizontal Injection Moulding Machine are reliable-power efficient-consistent-proven in the plastic moulding industry for trouble free long life Operation with minimum Maintenance cost. Available in standard sizes of 80 Tons to 400 Tons with Microprocessor Controls and Proportional Flow / Pressure Hydraulics to ensure repeatability with high production rates. We also develop and deliver customise requirement horizontal injection moulding machine for our clients.

Horizontal Injection Moulding Machine provides the flexibility to generate designs forms in a wide range of sizes from small to large plastic products, and can be used to manufacture a wide range of solid parts such as bottle caps, containers, computers, electronic housings, agricultural products, toys, machinery components, television components, outdoor furniture, and much more.

Advantages Of Horizontal Injection Moulding Machine

- Capability to execute tasks at a high pace of production.

- Very less material loss.

- Product finishing time is minimal.

- Accurate tolerance repeatability

- Due to auto product ejection labour cost is low.

- A variety of plastic materials are available for various plastic products

Key Characteristics Of Horizontal Injection Moulding Machine

High

Productivity

Low Power Consumption

Precision & Consistency

Robust Construction

Horizontal Injection Moulding Machine Specification

Capacity: 80 to 400 Ton Locking

Clamp Style: Toggle Locking

Clamping Force: 80 to 400 Ton

Machine Structure: Horizontal Injection Moulding Machine

Machine Series: GPPS Series

Material: GPPS Plastics & PVC/UPVC Plastic

Maximum Injection Pressure: 2175 TO 2279 Bar

Horizontal Injection Moulding Machine Features

Horizontal Injection Moulding Machine Videos

Horizontal Injection Moulding Machine Price

The price of our Horizontal injection moulding machine can differ significantly depending on its type, size, and features. The type of machine needed often corresponds to the type of plastic products being manufactured. Additionally, certain machines may require supplementary components. Moreover, the cost of the machine is influenced by its type; for instance, hydraulic machines tend to be less expensive compared to automatic ones. Considerations such as installation, support, and maintenance should also be factored in when inquiring about the price of a machine. KSB’s horizontal plastic injection moulding machine range is between 15 and 45 lakh. For a more precise pricing estimate, please reach out to us at +91-9824023849 or sales@ksblion.co.in.

Automatic plastic injection Moulding Machine

At KSB Machinery, we pride ourselves on being a leading automatic plastic injection moulding machine manufacturer in India with years of experience & commitment to excellence. Our machines are designed to meet the diverse needs of various industries, offering both standard & customizable solutions.